Technology Spotlight: HISENSE HVAC

HISENSE : The 2nd Largest VRF Manufacturer in the world

Hisense has emerged as a significant player in the HVAC industry, diversifying its product portfolio beyond consumer electronics and appliances. With a strong focus on technological innovation and sustainability, Hisense offers a comprehensive range of HVAC solutions, including air conditioners, heat pumps, and air quality products. Hisense global presence aims to cater to residential and commercial markets worldwide. Leveraging their reputation for innovation and brand recognition, Hisense has become a notable player in the HVAC sector, delivering energy-efficient and environmentally responsible heating and cooling solutions to consumers and businesses alike. Notably, Hisense holds the distinction of being the second largest VRF (Variable Refrigerant Flow) manufacturer in the world.

![]()

What is Hisense VRF?

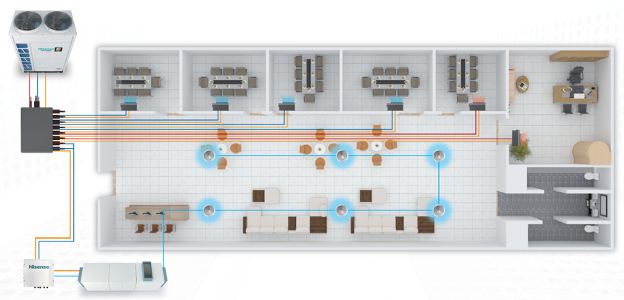

Variable Refrigerant Flow (VRF) is also known as variable refrigerant volume. It is an advanced method of air conditioning. The flow of Hisense VRF refrigerant can be varied according to the cooling and heating needs of individual zones, while the room temperature can be kept in the required range during occupied and unoccupied times, which improves comfort levels while saving energy. This type of system consists of a number of indoor units that are connected to one outdoor unit.

The indoor units can be of different styles and capacities to match each zones requirement, and can be controlled individually. The overall refrigerant flow depends on how many indoor units are working. The intelligence control system of Hisense VRF enables switching between the heating and cooling modes.

OUR PRODUCTS

Hi-FLEXi S Heat Recovery

The Hi-FLEXi S Series Heat Recovery system is a versatile and efficient solution for commercial and industrial applications. You can connect it with a Switch Box, allowing for the integration of indoor units and AHUs, and maximizing energy efficiency through air-side heat recovery. With a capacity ranging from 6 to 38 tons, it caters to various cooling and heating demands.

The system holds AHRI and ETL certifications, ensuring its performance and safety standards. Overall, it provides a reliable and effective heat recovery solution for creating a perfect indoor climate control system.

Heat Pump – Cooling Mode

Heat Pump – Heating Mode

Heat Recovery – Simultaneous Cooling and Heating

Hi-Smart H Series

The Hi-Smart H Series is a state-of-the-art side flow product designed to prioritize customer comfort and meet various application needs. With capacities ranging from 2 to 10 tons, it offers flexible cooling and heating options.

The system holds AHRI and ETL certifications, ensuring performance and safety standards are met. Overall, the Hi-Smart H Series provides efficient and comfortable climate control for both commercial and residential use.

New Refrigerant Piping

Connection with Flare-nut Branch Pipe Hisense’s innovative approach to refrigerant piping connections represents a significant breakthrough in the industry. By introducing flare-nut branch pipe connections, they have revolutionized the traditional method of joining refrigerant copper pipes, replacing complex brazing processes with a simpler and safer alternative.

This innovation not only enhances convenience but also contributes to a more efficient and user-friendly refrigeration system installation process.

INDOOR UNITS

AHU Connection Kit

The Hisense AHU-kit integrates external heat exchangers of Air-handling units (AHU) with a Hisense VRF system, providing flexible air conditioning solutions. It offers three control types for AHU applications: Inlet air temperature control, outlet air temperature control, and duty signal control. This integration enhances the system’s versatility and efficiency, catering to various commercial and industrial needs